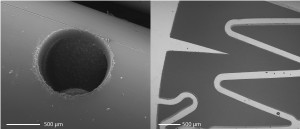

Femtosecond laser micromachining of medical device materials. Left: 1-mm diameter hole in 3-mm diameter, 250-µm thick bioabsorbable tubing. Right: cut pattern in 5-mm diameter, 50-µm thick Nitinol tubing.

With FCPA lasers, it is feasible to avoid modification of device materials, which are of concern when CW or long pulse lasers are used. UV laser use is of specific concern for organic materials. Furthermore, thermally-induced change of the surrounding materials of the laser focal spot needs to eliminated, or minimized to as low as possible. With FCPA lasers, high precision micromachined parts can be made without a large HAZ (heat affected zone) debris field, recast, or burrs. This is important for manufacturing medical devices without excessive post-processing steps.