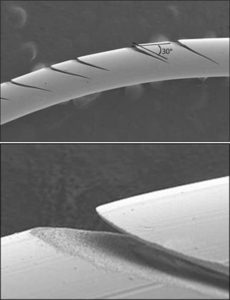

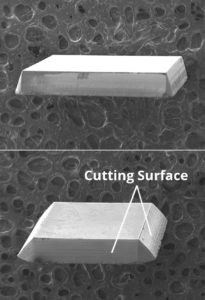

FCPA laser processed a chip breaker into a cutting tool made of diamond.

A chip breaker is a portion of the tool bit in a turning machine which breaks the chips generated from a workpiece into small pieces. This action increases the productivity of the work, the safety of the machine, and the life span of the tool. The chip breaker shown on this carbide cutting tool is classified as a “groove-type” chip breaker, wherein the laser removed sections of the tool to create the grooves. FCPA lasers can process diamond and CBN chip breakers onto the cutting tool, optimizing the structure of the whole tool.