The ultrafast dynamics of the laser interaction with material is governed by the energy transfer time from the laser light to the material. In most cases, primarily the electrons absorb the energy from the light, becoming hot. Subsequently the electron energy is transferred to the cold lattice atoms, or molecules. The time required for this transfer is characterized with phonon emission time. If electrons and phonons are in a thermal equilibrium state, the state can be described by a single temperature. This is called being thermalized. In practice, the hot/cold and thermal/non-thermal regime can coexist, depending on the details of the interacting laser and material parameters.

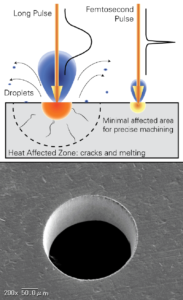

For laser material processing, the important question is, how much energy of the absorbed light contributes to the ablation of the material. Therefore, it is more practical to trace the heat generated and dissipated in the material, which is described as the heat affected zone (HAZ). As shown in the diagram above, the extended HAZ area results in producing molten debris, casts and other undesirable formations of materials. Many precision parts these days require processing approaches that eliminate or minimize HAZ.