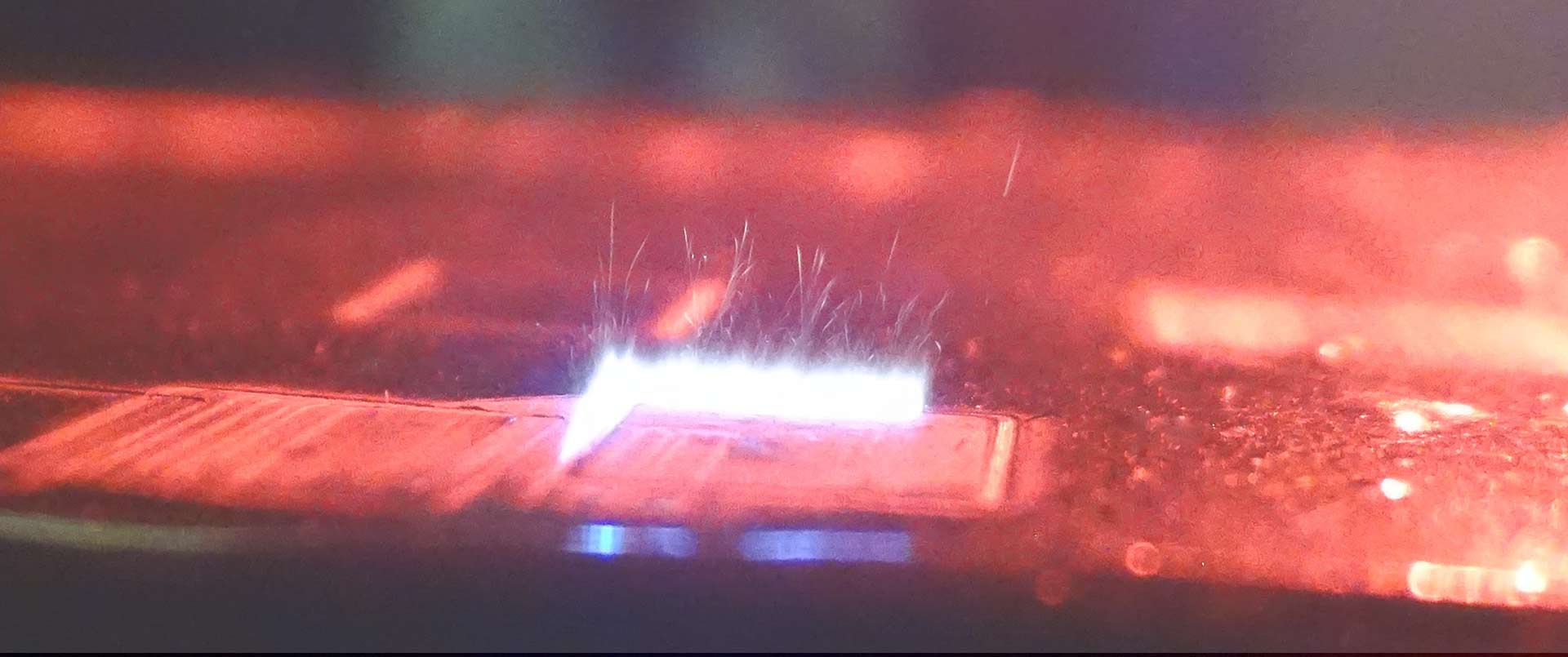

The ablation process is the underlying mechanism for laser machining. Conventional pulsed-laser machining techniques dissociate matter at atomic and molecular levels via the deposition of laser radiation. The absorbed laser energy is transferred to the atomic and molecular lattice of the material, which causes the material to be ablated. At the same time, this energy is eventually converted into heat which dissipates out of the laser spot volume beyond the duration of the laser pulse.

However, by using femtosecond (10-15 seconds) lasers, a surgically clean and highly localized laser ablation is feasible without collateral damage or modification of the surrounding material. Femtoseconds are the time scale in which a mechanism called cold ablation can occur.

What is Cold Ablation?

Strictly speaking, the concept of cold ablation is an ablation that occurs during the athermal state of the material in the dynamics of the femtosecond laser absorption. The idea is to ablate material before it is in a full thermal equilibrium state, giving it less chance to build up heat that would spread away from where the laser energy is directly absorbed.

Let us first consider the details on how the laser energy is transferred to the material. When the extremely short laser pulse hits the material, the laser energy is deposited into the photo-excited electronic subsystem of the atoms rather than the atomic and molecular lattices. If the absorption process occurs in an extremely short time scale, most of the material is in an athermal state: hot electrons in a practically cold atomic and molecular lattice.

The word “cold” originates from this concept. This happens in the earliest time scale as sufficient energy is transferred from the electron subsystem before reaching a thermalized state between the electrons and atoms systems, which is therefore also called athermal ablation. In this time scale often the electronic subsystem itself might not have reached its own thermalized state, making the definition of the athermal state complex. If all the energy of these athermal electrons could be used for ablating atoms or molecules directly out of the host material lattice, it would be the ideal scenario for the so-called cold ablation. Obviously, the first and foremost important requirement for this scenario to occur is the usage of ultrafast laser pulses.

In reality, however, the athermal ablation and thermalization of the material occur concomitantly unlike digitally tuning it on or off in the time. This makes the time span for the cold, athermal, or thermal ablation vastly overlap each other at different degrees of weights. Moreover, heat build-up and dissipation can occur in parallel, which moves the heat out of the laser spot volume by the electron subsystem and/or atomic or molecule lattice systems. Moreover, fast repetitive laser pulses are used for ablating material to boost up the ablation rate, which adds further complexities in almost all practical cases. This often leads to a highly elevated temperature in the material. The temperature is not necessarily high enough for ablation, but it can melt down the solid-state material.

Read More: A Guide to Femtosecond Lasers

Note that all the complex stories above depend very much on the material to be ablated. The time arrangement of the individual dynamics and the degree and weight of the overlaps can be quite different from material to material.

As laser ablation and micromachining have been adapted by broader industries, the technical terminologies have subsequently evolved to describe the phenomenological observation of the ultrafast laser ablation process minimizing the heat-affected zone.

Understanding Femtosecond Micromachining

One clear aspect is that the shorter the interaction time of the laser pulse—from nano- over pico- to femtosecond—with the material, the higher the contribution of non-thermal characteristics in the ablation result. This has been demonstrated for many materials by femtosecond lasers, demonstrating, indeed, another level of ultra-precise micromachining is feasible by femtosecond laser. In materials such as polymers, where collateral damage is highly prone to the heat build-up, a femtosecond laser has become a must-have tool over even a picosecond laser. Furthermore, micron-level precision ablation is only possible by femtosecond lasers with unparalleled high-quality non-thermal features.

If you like this article, you may be interested in our recent post Eliminating the Heat-Affected Zone

Historically, it was practically impossible to deposit the requisite levels of energy for industrial laser machining when focusing a beam onto matter for ultrashort durations. This challenge was overcome with the onset of fiber-chirped pulse amplification (FCPA) technology.

If you would like to learn more about cold ablation, or the applications of femtosecond micromachining with FCPA technology, simply contact a member of the team today.